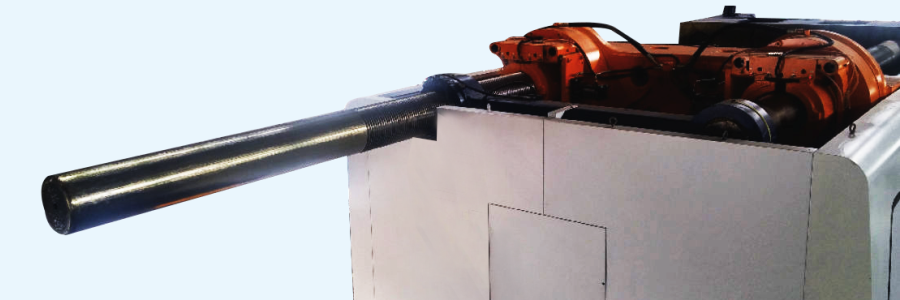

Horizontal Design Features

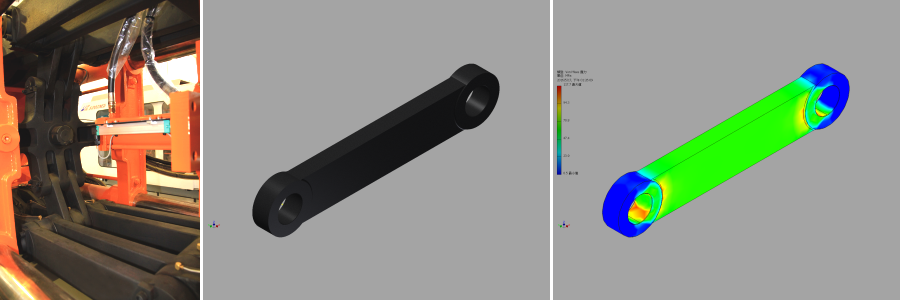

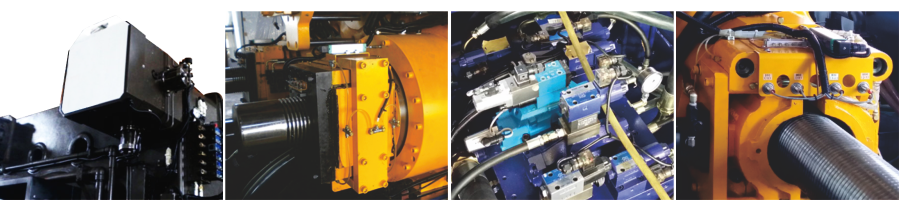

Horizontal Toogle Clamp

Inward Toggle Clamping

Cost-effective, Stable & Durable.

Years of experience with advanced designs for professional applications.

Dynamic computation with FAE analysis ensuring the mechanism durability.

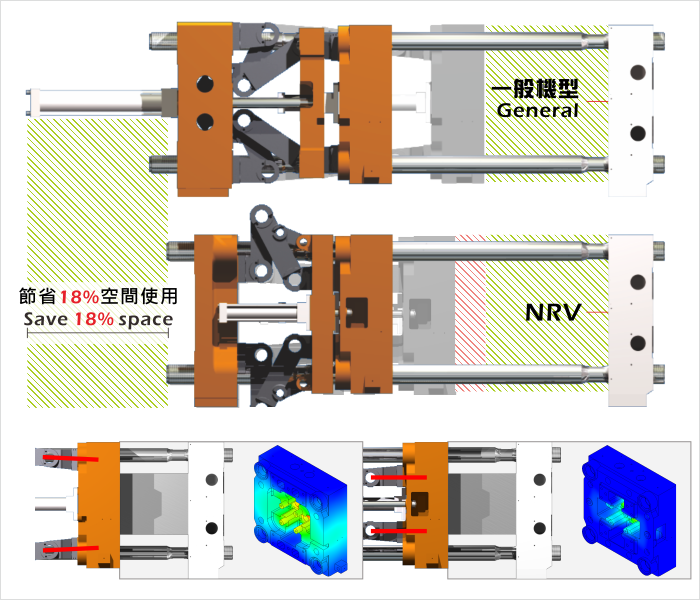

Interactive Outward Toggle

Compact Structure with Faster Clamping and Bigger Opening.

Shifted clamping cylinder reduced 18% machine length.

40% shortened clamping cylinder.

Enlarged opening stroke.

Precise alignment & centering ensuring parallel & collateral clamping movement.

Advanced cylinder design brought accurate positioning, ensuring robotic automation.

Platen deformation analysis.

Center-forced clamping with 55% minimized deformation, by FEA.

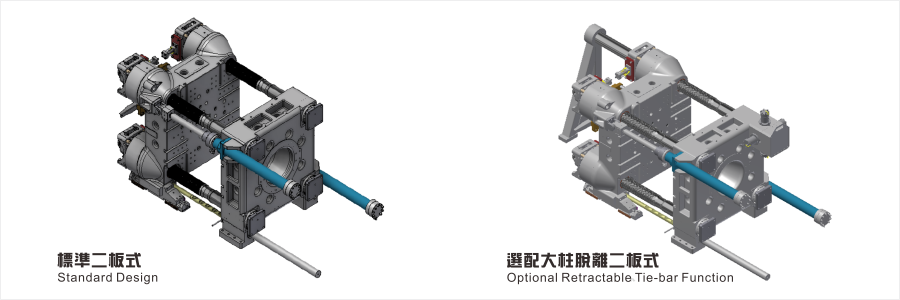

2-platen clamping system

Minimized machine length with maximized opening stroke.

20% ~ 30% less from machine length, compare with toggle design.

Less space required from a molding facility.

Built-in design with ejection cylinder.

Minimized machine length effectively.

Fully automatic mold-close adjustment ready.

Less time needed from mold change. Paten #I279312, Intellectual Property Office, MOEA, Taiwan.

Available option for additional stroke from opening.

Spare the larger machine needs for bigger opening stroke.

Available option with Retractable Tie-bar function.

With additional mold lifting module to accommodate jumbo machines in regular facility height.