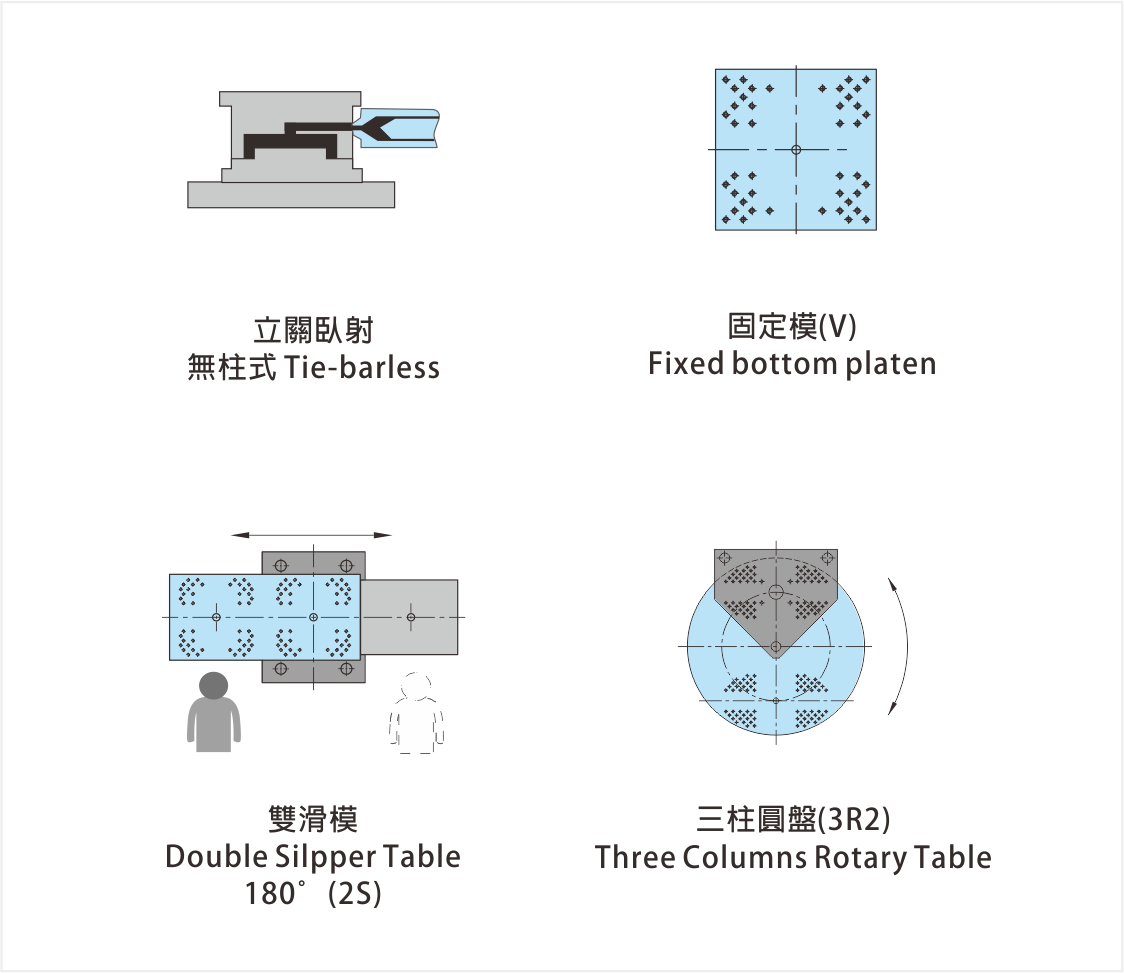

Vertical Design Features

YT Series

YT Vertical Clamping Horizontal Injection Four Columns Series

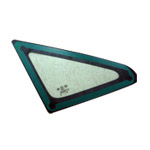

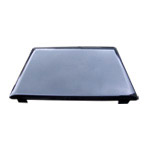

- Fixed mold (V) and the two sliding mold (2S) adopts four-column vertical pressure clamping for horizontal injection. Strong mechanical structure allows greater endurance for clamping force up to 500~ 800TON.

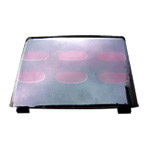

- Standard disc is vertical 3-column vertical pressure clamping. The two station design is for horizontal injection.

- With special needs, 4-columns vertical pressure clamping is available with the disc mold stations at 3 to 4.

- The nozzle can be adjusted in height level, easily for center level correction of mold feed into make mold design more convenient.

- Injection is smooth and powerful, suitable for forming larger fitting pieces. With a special L / D aspect ratio of the injection screw, it is more suitable for engineering plastics.

- Scalable computer programs, automatically removing, embedded devices, and other connections allow fully automatic operation of the whole machine.

- ─Two slide mold (2S) ─ (alternating two slide mold): One mold is in injection molding and the other is outside for removing and placing mosaic pieces. Operation safety and production efficiency is high.

- ─Round disc (R) ─ alternatively rotating back and forth at 180 ° horizontally to allow users to operate in a fixed plane for retrieval and inserting pieces. This makes the work more convenient.